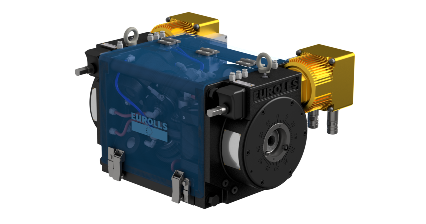

MOTORIZED SYSTEM

To meet the needs of intensive production, Eurolls has developed a motorized system for the automatic adjustment of the rolls in the cassettes placed at the final draft stage. These cassettes work in association with Boba25 control system. Utilizing a laser measurer positioned at the machine’s exit and performing 16,000 checks per second, it keeps the wire’s weight and mass consistent, working on the regulation of the rolls and the wire diameter. This system ensures a deviation of no more than 0.5 kg per 1,000 kg of wire produced. The system can be integrated with Ribs84 for real-time measurement of rib height, width, and pitch, which ensures strict compliance with company standards.

Advantages

Advantages

- Real time tracking of key metrics (hour/shift, product weight, etc.)

- Control of all parameters (temperature, speed, vibrations, water flow, etc.)

- Compliance with company standards

- Reduction of machine downtime, material waste and machine failures