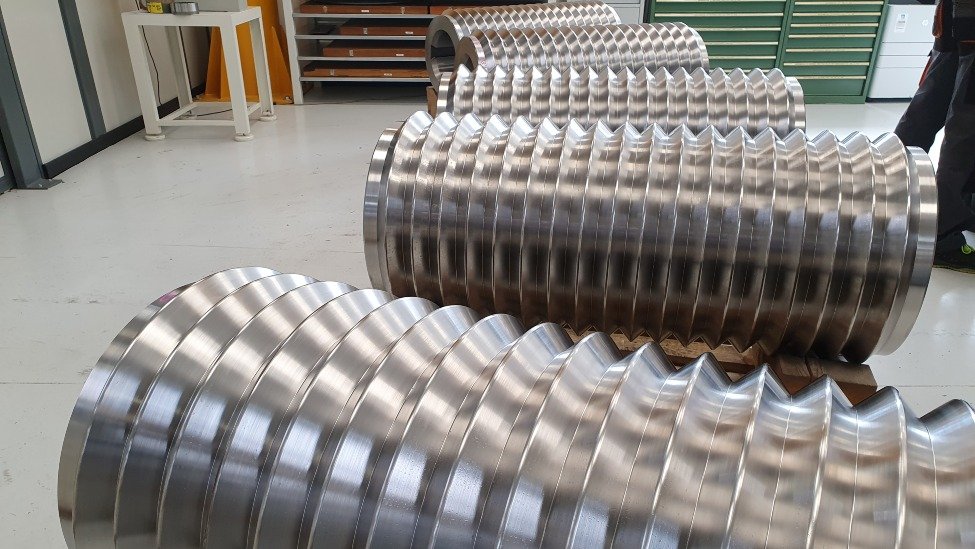

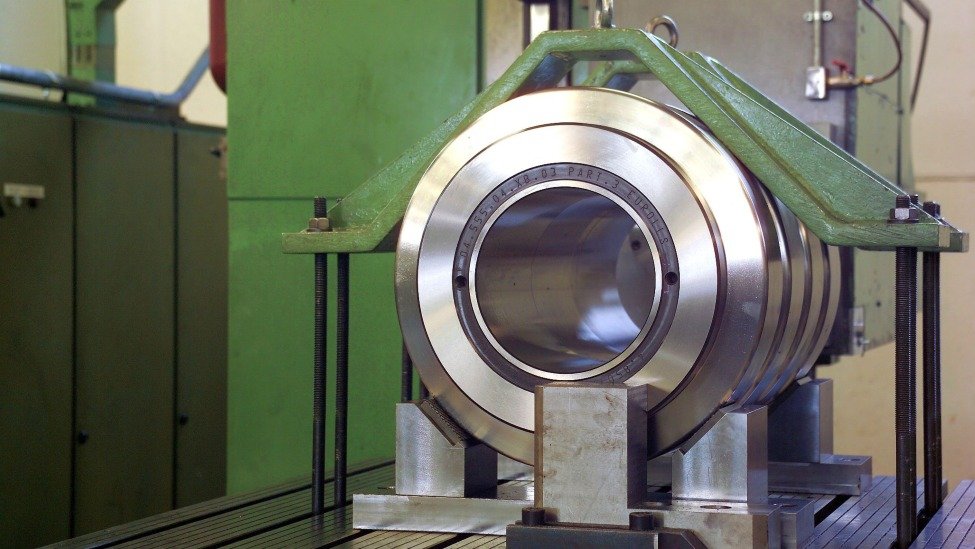

STRAIGHTENING ROLLS AND CYLINDERS

-

Material: Straightening rolls and cylinders are made from special high-yield steel. High-yield steel is a type of steel that has been designed and manufactured to have higher strength and toughness compared to regular steel. This makes it suitable for handling the stresses and forces involved in straightening and shaping metal materials.

-

Forging: The rolls and cylinders are forged. Forging is a manufacturing process where metal is shaped using localized compressive forces. In this case, high-yield steel is heated and then shaped under pressure to create the desired form of the rolls and cylinders. Forging helps enhance the material's strength and durability.

-

Heat Treatment: The forged rolls and cylinders undergo heat treatment, which involves subjecting the metal to controlled heating and cooling processes to achieve specific mechanical properties. This can include improving hardness, toughness, and other desirable characteristics in the steel.

-

Straightening Machines: The rolls and cylinders are used on straightening machines designed to correct the shape of various metal products. When metals are processed through rolling mills or other machinery, they can develop deformities, bends, or curvatures. Straightening machines, equipped with these specialized rolls and cylinders, apply controlled pressure to reshape and restore the metals to their intended shape.

- Product Types: The straightening machines equipped with these rolls and cylinders are capable of producing different shapes, including:

- "Z" Shapes: These might refer to metal products that have a zigzag or "Z" shape when viewed from the end.

- "L" Shapes: These refer to metal products with a 90-degree angle, forming an "L" shape.

- "T" Shapes: These refer to metal products with a T-like profile, typically with a horizontal top and a vertical stem.

- Hot Rolled Angles: These are likely metal angles that have been hot rolled to achieve specific dimensions and properties.

In summary, the use of special high-yield steel, forging, and heat treatment in the manufacturing of straightening rolls and cylinders highlights the importance of durability and strength in these components. They play a crucial role in shaping and correcting metal products using straightening machines, allowing for the production of various shapes and angles in metalworking processes.

Other products:

Different solution of motorized rolls for wire pulling, recommended for critical wire passages.